OUR HEAVY-DUTY INDUSTRIAL HOISTS provide a fast and convenient way to lift heavier payloads of personnel and materials in even the most demanding conditions at various locations.

EACH HEAVY-DUTY HOIST is designed to meet the requirements of a given location and its conditions, with lifting capacities from 1500 kilograms up to 2000 kilograms.

ALL MODELS ARE MODULAR and provide reliability and low cost of ownership, making it a profitable investment in a range of industries.

SPECIAL CONDITIONS at different fields of application require flexible and applicable access technology. In order to be one step ahead of our competitors, we are constantly working to improve and modify the machines.

THE SAFETY BRAKE ensures that the cage will not fall down, even in a complete breakdown of a drive unit. A mechanical, spring-loaded safety brake is a standard safety feature in every model. It improves the safety and reliability of our hoists. The long-lasting safety brake is well protected from any dirt or dust and is practically maintenance-free.

HOIST CAGES are available in several sizes and different door positions. But since the hoist design is modular, the width and depth of the cage may be increased in increments of 12 cm. A front door, back door and large side door are available.

THE GROUND STATIONS are bolted on a concrete or similar foundation. The standard ground station is equipped with one door but there are optionally available a back door and a wider side door.

A CABLE TROLLEY SYSTEM guides the electrical cable, allowing it to run smoothly while the cage is moving.

THE HOISTS are equipped with an overload control system, preventing the use of the hoist if it is loaded by 10% over it’s lifting capacity.

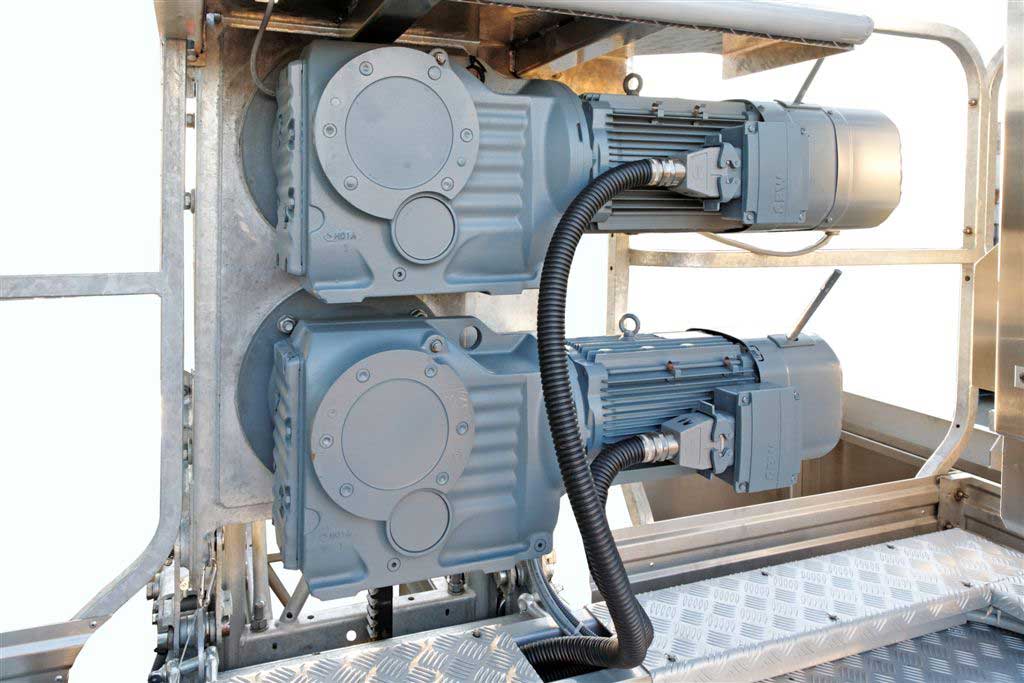

THE LIFT DRIVE is provided by one unit installed above the car roof, equipped with two electric motors with helical-bevel gears. In case of emergency, it is possible to lower the car and to stop the car precisely at the nearest landing.